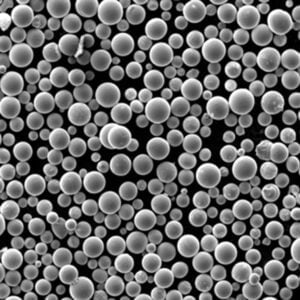

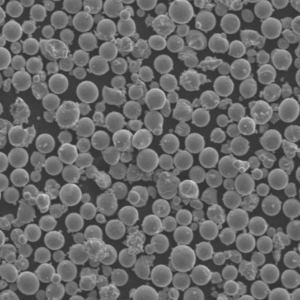

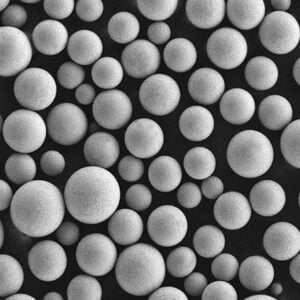

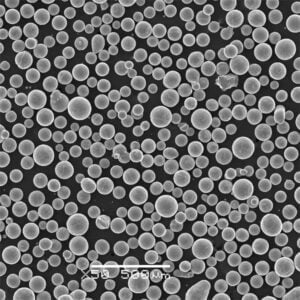

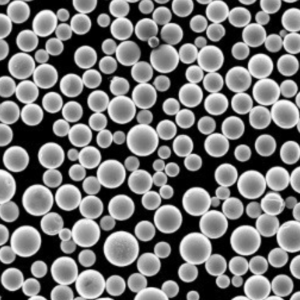

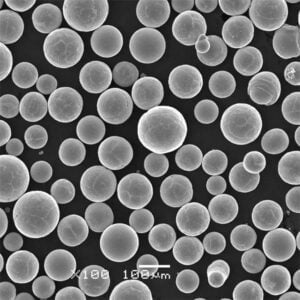

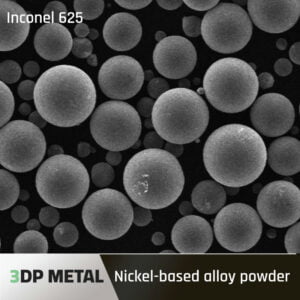

Gas atomization is a specialized manufacturing process to produce fine metallic powders with precise composition and consistent particle sizes. The powders find application across automotive, aerospace, medical, and industrial sectors.

개요 gas atomized powder

표 1: Summary of the Gas Atomization Process

| 매개변수 | 세부 정보 |

|---|---|

| 원자재 | Metals like titanium, aluminum, steels, nickel alloys in form of ingots, electrodes or wire |

| 프로세스 원칙 | Melting feedstock and breaking up molten metal stream into fine droplets using high pressure gas jets |

| Atomizing Gases | Air, Nitrogen, Argon |

| Solidification Rate | 10^3 – 10^5 °C/s |

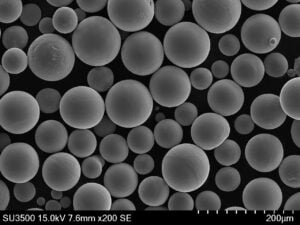

| Final Products | Spherical metal powders with controlled size ranging from 10 microns to 500 microns |

Controlled gas flow rates, precise atomization nozzles and specialized cooling designs enable the production of fine, spherical powders.

응용 Gas Atomized Powders

표 2: Major Application Areas of Gas Atomized Powder

| 산업 | 애플리케이션 예시 |

|---|---|

| 적층 제조 | 3D printing of aerospace and medical components |

| 분말 사출 성형 | Manufacture of small, complex metal parts with better mechanical properties |

| 용사 코팅 | Feedstock powder for wear and corrosion resistant coatings |

| 금속 사출 성형 | Small precision components like gears and cutting tool tips |

| Brazing Pastes | Nickel and aluminum based brazing filler metal powders |

The consistent powder characteristics like particle size distribution, purity and morphology make gas atomized powders a preferred feedstock across powder metallurgy processes.

Advantages Over Alternatives

표 3: Benefits of Gas Atomized Powder Over Other Types

| 매개변수 | 혜택 |

|---|---|

| 파티클 모양 | Highly spherical morphology gives excellent flowability |

| 입자 크기 제어 | Consistent microstructure which minimizes defects in finished components |

| Composition Consistency | Precise control over alloying elements ensures reliable mechanical properties |

| 비용 효율성 | Higher yields compared to water atomization with easier powder recovery |

| Product Customization | Flexibility to tailor powder composition and particle sizes as per application |

The combination of precision, consistency and flexibility makes gas atomization a versatile powder production technique at commercial scales.

일반 사양

표 4: Typical Specification Range for Gas Atomized Powders

| 매개변수 | 범위 |

|---|---|

| 재료 | Titanium, Aluminum, Steels, Nickel, Copper alloys |

| 입자 크기 | 10 to 500 μm |

| 입자 크기 분포 | Tight distribution with SG > 0.9 |

| 산소 함량 | 100 – 1000 ppm range |

| 질소 함량 | < 100 ppm |

| 모양 | Highly spherical > 80% |

| 겉보기 밀도 | Up to 65% of pure metal |

The properties can be tailored over a wide range as per intended usage across industries.

장점과 단점

표 5: Advantages and Limitations of Gas Atomization

| 장점 | 단점 |

|---|---|

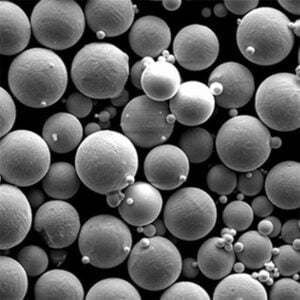

| Consistent particle characteristics | Limitations on alloying additions like reactive elements |

| Cost effective for higher volumes | Initial equipment capital cost relatively high |

| Wide range of alloy families | Handling of fine pyrophoric powders requires care |

| Scale-up to tonnage quantities feasible | Post-processing often required to remove satellites and fines |

Despite growing expertise globally, gas atomized powder still requires significant process development and qualification efforts by end-users to apply successfully for niche applications.

자주 묻는 질문

Q: Does gas atomization allow single crystal powder production?

A: Very challenging – the rapid solidification rates create fine grained microstructures. Specialized variants like Electrode Induction-melting Gas Atomization (EIGA) can yield some fraction of single crystal particles.

Q: What is the typical nitrogen content range for gas atomized titanium powder?

A: With best practices, N2 levels of 100-500 ppm can be achieved for gas atomized titanium powder. This expands AM capability versus other variants with higher oxygen/nitrogen which negatively impacts mechanical performance.

Q: What is the key difference between gas and water atomized metal powders?

A: Gas atomization allows better particle shape and size control. Water atomization yields faster cooling rates but experiences more oxidation and satellite particle issues during powder production and recovery.