블로그

모든 컬렉션

가스 분무 금속 분말

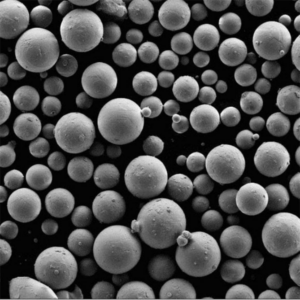

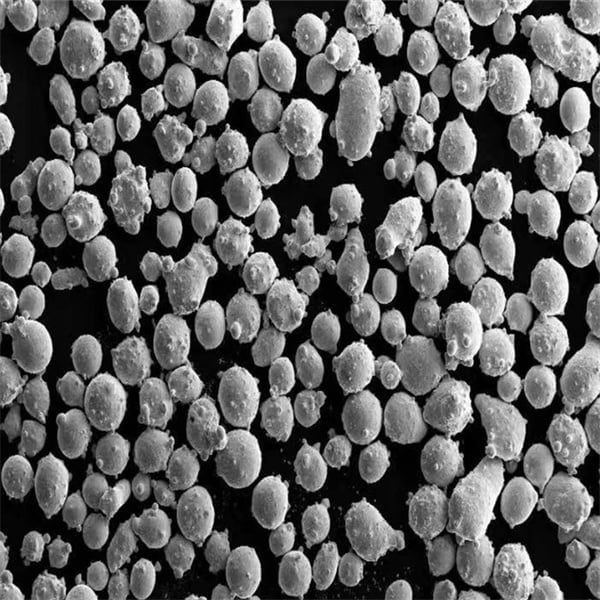

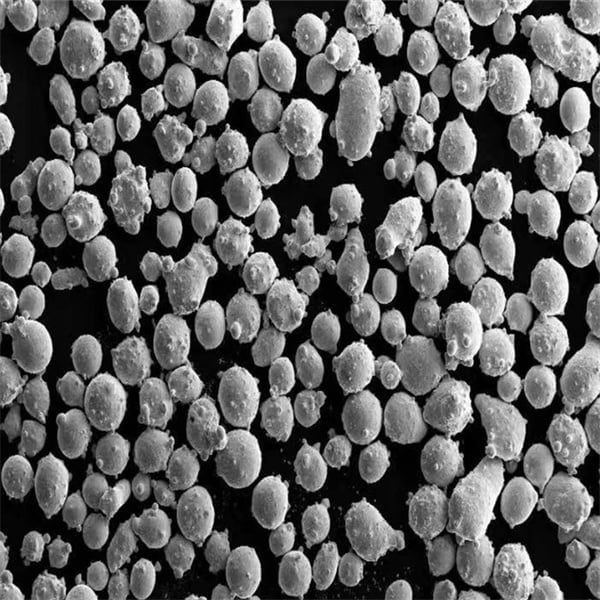

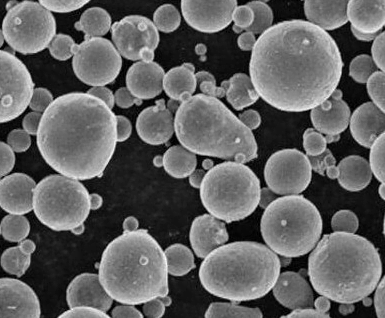

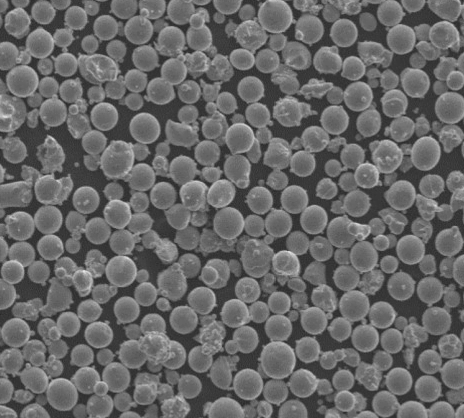

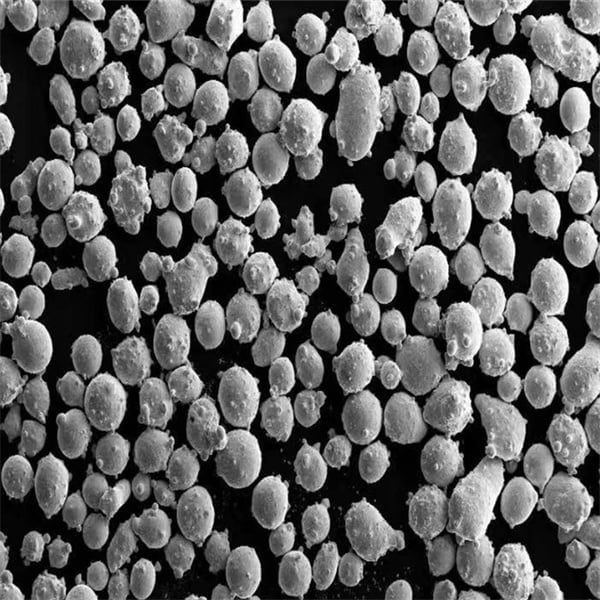

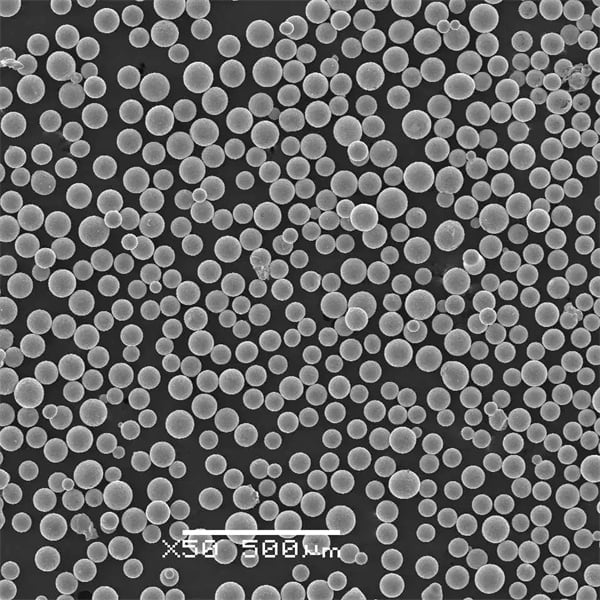

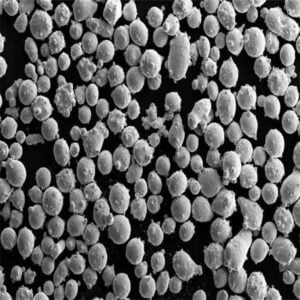

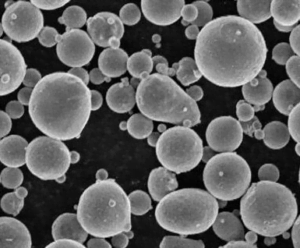

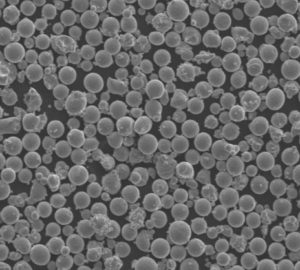

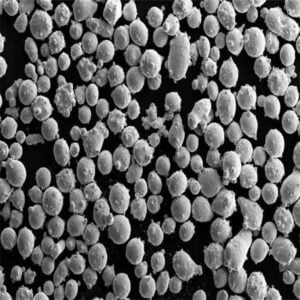

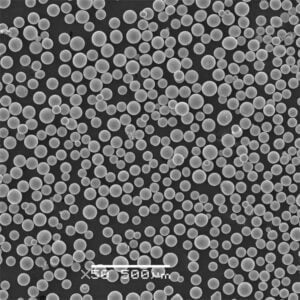

가스 분무 금속 분말 개요 가스 분무 금속 분말은 용융 합금 공급 원료를 고속 불활성 가스 제트로 분무하여 생산되는 금속 미립자 물질을 말합니다. 이는 적층 제조, 금속 사출 성형 및 기타 응용 분야에 이상적인 구형 형태를 부여합니다. 가스 원자화 기능: 계속 읽기

인코넬 3D 프린팅 부품

인코넬 3D 프린팅 부품 개요 인코넬 3D 프린팅 부품은 적층 제조(AM) 방법을 사용하여 인코넬 초합금 분말로 제조된 부품을 말합니다. 인코넬 등급은 내열성 및 내식성이 뛰어나고 강도가 높기 때문에 항공우주, 발전 및 기타 까다로운 응용 분야에 이상적으로 적합합니다. 주요 특성

티타늄 알루미늄 합금

개요 티타늄 알루미늄 합금은 티타늄과 알루미늄이 혼합된 금속 재료의 일종입니다. 가볍고 강도가 높으며 고온에서 부식 및 산화 저항성이 뛰어납니다. 티타늄 알루미늄 합금은 다음과 같은 특성으로 인해 항공우주 및 자동차 분야에서 중요한 고온 구조 재료로 간주됩니다.

가스 분무 금속 분말

가스 분무 금속 분말은 금속 사출 성형(MIM), 적층 제조, 프레스 및 소결, 용사 코팅, 분말 야금 등의 응용 분야를 위한 미세한 구형 금속 분말을 생산하는 재료 가공 방법을 말합니다. 가스 분무에서는 고압 불활성 가스를 사용하여 용융 금속 합금을 방울로 분해합니다.

텅스텐 금속 분말

Overview of tungsten metal powder Tungsten metal powder refers to fine particulate material composed primarily of elemental tungsten for use in various industrial applications. Key properties include extremely high density, strength, hardness, and high temperature durability. Common applications of tungsten powder include: Tungsten is considered a critical raw material for its unique performance combined with

가스 분무 금속 분말

Overview of gas atomized metal powder Gas atomized metal powder refers to metallic particulate materials produced by atomizing molten alloy feedstock with high velocity inert gas jets. This imparts a spherical morphology ideal for additive manufacturing, metal injection molding, and other applications. Gas atomization features: Continue reading to learn about composition options, particle qualities, usage

인코넬 3D 프린팅 부품

Overview of inconel 3d printed part Inconel 3D printed parts refer to components fabricated from Inconel superalloy powders using additive manufacturing (AM) methods. Inconel grades offer exceptional heat and corrosion resistance combined with high strength, making them ideally suited to aerospace, power generation, and other demanding applications. Key properties of Inconel 3D printed parts: Continue

고온 철분 분말

Overview High temperature iron powders are specialized metallic powders made from iron-based alloys designed to operate at elevated temperatures exceeding 850°C without rapidly losing strength. Conventional iron and steel powders oxidize and deteriorate faster beyond this threshold. By carefully tailoring powder chemistry and processing treatments, high temperature strength and environmental resistance is enhanced. Key application

금속 분말 생산

Overview Metal powders are fine metal particles used as feedstock for manufacturing techniques like additive manufacturing, metal injection molding, and powder metallurgy pressing and sintering. Producing advanced specialty metal powders with precise control of chemistry, particle size distribution, morphology, and microstructure is critical to properties of finished components. There are various methods used for large

티타늄 알루미늄 합금

Overview Titanium Aluminum Alloys are a class of metallic materials that contain a mixture of titanium and aluminum. They are lightweight, have high strength, and excellent corrosion and oxidation resistance at high temperatures. TiAl alloys are considered an important high-temperature structural material for aerospace and automotive applications due to their unique combination of properties. Their

전자빔 제조

Electron beam manufacturing refers to an additive manufacturing process that uses a focused beam of high-energy electrons to selectively melt and fuse metallic powder particles together layer-by-layer to directly fabricate complex 3D components. Also known as electron beam melting (EBM) or electron beam powder bed fusion, the process offers capabilities like build rate, material properties,

MIM 적층 제조

mim additive manufacturing refers to an industrial process to produce small, complex metal parts at high volumes. A composite metal powder feedstock is molded into a green-state shape using injection molding equipment, debound, and then sintered to achieve full density. MIM leverages the geometric flexibility of polymer injection molding and green-forming with the performance capability

가스 분무 금속 분말

Gas atomization metal powder refers to a material processing method to produce fine spherical metal powders for applications like metal injection molding (MIM), additive manufacturing, pressing and sintering, thermal spray coatings, powder metallurgy, and more. In gas atomization, molten metal alloys are disintegrated into droplets using high pressure inert gas jets. The droplets rapidly solidify

SLM 제조 이해

slm manufacturing is a powder bed fusion additive manufacturing process used across industries. This guide provides a comprehensive look at SLM – how it works, materials, applications, advantages/disadvantages, system suppliers, and more. Overview of Selective Laser Melting (SLM) slm manufacturing is an additive manufacturing process that uses a laser to selectively melt metal powder layer-by-layer

제품

인기 판매 제품

3D 프린팅 및 적층 제조용 금속 분말

연락처 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731