블로그

모든 컬렉션

알루미늄 합금 7050 분말

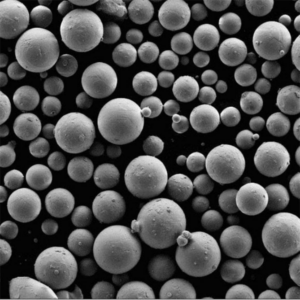

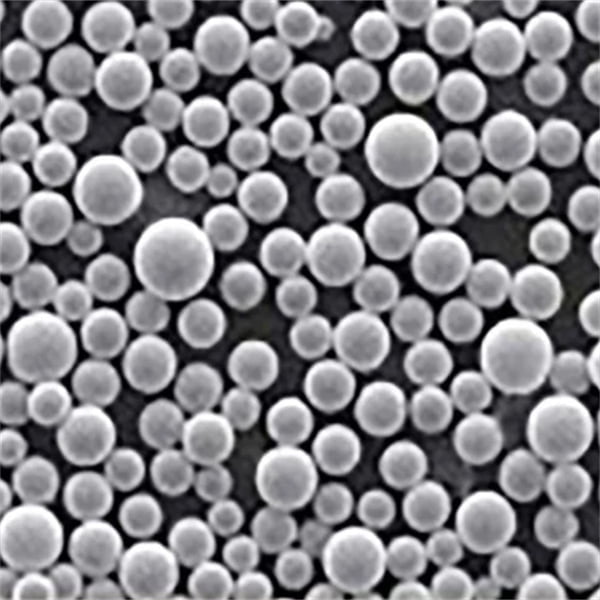

aluminium alloy 7050 powder is a high-strength aerospace alloy also available in powder form for additive manufacturing and other powder metallurgy applications. With zinc and magnesium as primary alloyants, this 7xxx series alloy demonstrates superior mechanical properties ideal for critical structural components. Overview of aluminium alloy 7050 powder Property Description

고밀도 텅스텐 분말

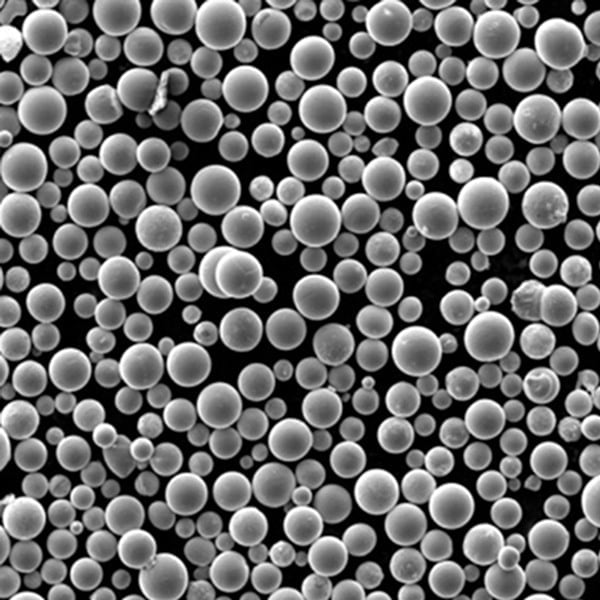

고밀도 텅스텐 분말은 금에 근접하는 텅스텐의 매우 높은 고유 밀도로 인해 모든 금속 분말 중에서 가장 높은 밀도를 가지고 있습니다. 이러한 고유한 특성 덕분에 다양한 분야에서 고강도 분말 압착 및 소결 방법을 활용하여 컴팩트하고 무게 효율적인 부품을 설계할 수 있습니다. 텅스텐 분말 개요 밀도

니켈 알루미나이드 분말

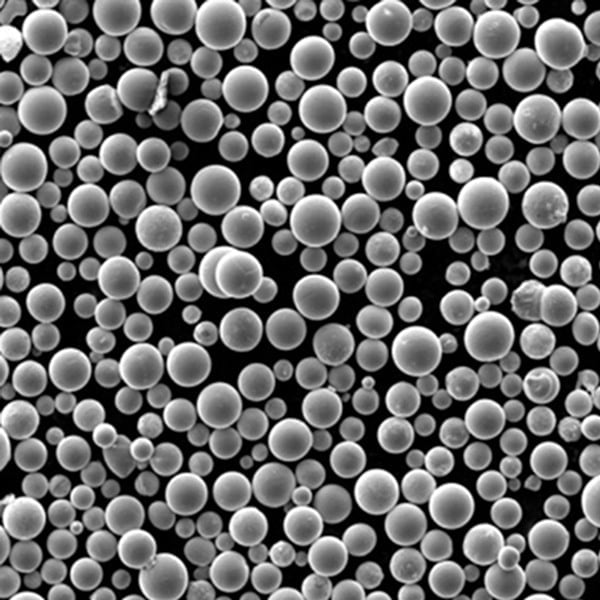

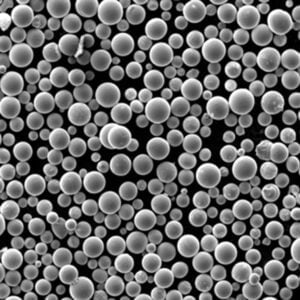

니켈 알루미나이드 분말 개요 니켈 알루미나이드 분말은 니켈(Ni)과 알루미늄(Al) 원자가 약 1:1의 비율로 구성된 금속 간 화합물입니다. 높은 강도와 경도, 고온에서 우수한 내식성 및 내산화성, 낮은 밀도, 우수한 내마모성이 특징입니다. 니켈 알루미나이드

니켈 합금 금속 분말

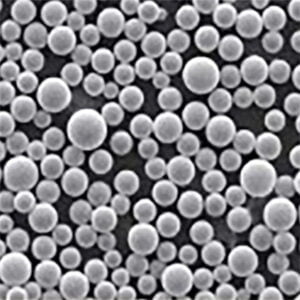

니켈 합금 금속 분말은 다양한 니켈 합금 조성의 분말 야금 형태를 말합니다. 이러한 분말은 금속 사출 성형, 적층 제조, 분말 압착 및 소결 등의 방법을 통해 니켈 합금 부품 및 구성 요소를 제조하는 데 사용할 수 있습니다. 니켈 합금 금속 분말 개요 니켈 합금 분말은 독특한

몰리브덴 티타늄 분말

몰리브덴 티타늄 분말 개요 몰리브덴 티타늄 분말은 원자화 공정을 통해 생산된 각 원소의 미세한 금속 입자를 말합니다. 높은 강도, 경도 및 내열성을 나타냅니다. 분말은 개별적으로 또는 고성능 합금 제조를 위한 블렌드로 사용됩니다. 입자 크기 분포가 제어되어 그물에 가까운 복잡한 형상을 만들 수 있습니다.

인코넬 625 분말

인코넬 625 분말은 니켈-크롬-몰리브덴 합금 분말로 우수한 강도, 내식성 및 최대 1000°C의 고온 성능으로 잘 알려져 있습니다. 이러한 특성의 조합으로 인해 인코넬 625는 항공우주 부품부터 화학 처리 장비에 이르기까지 까다로운 응용 분야에 다용도로 사용되는 초합금입니다. 이 가이드에서는 다양한 유형의 인코넬을 다룹니다.

적층 제조 구리

additive manufacturing copper demonstrate expanding use across additive manufacturing methods, enabling fabrication of highly conductive parts with useful mechanical performance. As one of few metal options across powder bed fusion, binder jetting and directed energy deposition processes, understanding key powder attributes promises growth in applications. Overview of additive manufacturing copper Additive manufacturing using copper promises:

알루미늄 합금 7050 분말

aluminium alloy 7050 powder is a high-strength aerospace alloy also available in powder form for additive manufacturing and other powder metallurgy applications. With zinc and magnesium as primary alloyants, this 7xxx series alloy demonstrates superior mechanical properties ideal for critical structural components. Overview of aluminium alloy 7050 powder Property Description Alloy AA7050 UNS Number A97050

고밀도 텅스텐 분말

High density tungsten powder possesses the greatest density among all metallic powders owing to tungsten’s extraordinarily high intrinsic density approaching that of gold. This unique attribute allows advanced design of compact, weight-efficient components across diverse sectors harnessing heavy powder pressing and sintering methodologies. Overview of tungsten powder With a density of 19.3 g/cm3 in solid

니켈 알루미나이드 분말

Overview of nickel aluminide powder Nickel aluminide powder is an intermetallic compound composed of nickel (Ni) and aluminum (Al) atoms in an approximate ratio of 1:1. It is characterized by high strength and hardness, excellent corrosion and oxidation resistance at high temperatures, low density, and good wear resistance. Nickel aluminide powders are produced by gas

금속 분무 시스템

Metal atomization is a manufacturing process where metal is turned into powder form by breaking up molten metal into tiny droplets. This powder can then be used to manufacture parts through methods like metal injection molding, hot isostatic pressing, additive manufacturing, and more. Metal atomization systems are the equipment used to carry out this process.

금속 분말 분무

Metal powder atomization is a critical technology for producing fine metallic powders with specialized characteristics. This guide covers the fundamentals, methods, applications and commercial landscape of metal powder atomization. What is Metal Powder Atomization? Metal powder atomization refers to industrial processes that turn molten metal alloys into fine liquid droplets, rapidly solidifying them into powder

니켈 합금 금속 분말

Nickel alloys metal powders refer to powder metallurgy forms of various nickel alloy compositions. These powders can be used to manufacture nickel alloy parts and components through methods like metal injection molding, additive manufacturing, and powder pressing and sintering. Overview of Nickel Alloys Metal Powder Nickel alloy powders provide unique properties like high strength, corrosion

316 금속 분말

316 metal powder is a type of stainless steel powder composed primarily of iron, chromium, nickel, and molybdenum. It is widely used in various powder metallurgy, additive manufacturing, and metal injection molding applications due to its excellent corrosion resistance, good mechanical properties, and ability to be 3D printed or sintered into complex parts. Overview of

몰리브덴 티타늄 분말

Overview of molybdenum titanium powders molybdenum titanium powders refer to fine metallic particles of each element produced through atomization processes. They display high strength, hardness and heat resistance. The powders are used individually or as blends for manufacturing high performance alloys. Their controlled particle size distribution allows complex near-net shape components to be built up

인코넬 625 분말

Inconel 625 powder refers to a nickel-chromium-molybdenum alloy powder known for excellent strength, corrosion resistance, and high temperature performance up to 1000°C. This combination of properties makes inconel 625 a versatile superalloy for demanding applications ranging from aerospace components to chemical processing equipment. This guide covers different types of inconel 625 powder including gas atomized

제품

인기 판매 제품

3D 프린팅 및 적층 제조용 금속 분말

연락처 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731