3D 프린터 파우더 공급업체

3D 프린팅 기술은 분말 소재를 사용하여 레이어별로 물체를 제작합니다. 올바른 파우더를 선택하는 것은 부품 품질, 기계적 특성, 정확도, 디테일 해상도 및 표면 마감에 매우 중요합니다. 이 문서에서는 주요 3D 프린팅 프로세스에 사용되는 다양한 유형의 파우더와 그 구성, 주요 특성, 응용 분야, 적용 사례에 대한 개요를 제공합니다.

3D 프린팅 기술은 분말 소재를 사용하여 레이어별로 물체를 제작합니다. 올바른 파우더를 선택하는 것은 부품 품질, 기계적 특성, 정확도, 디테일 해상도 및 표면 마감에 매우 중요합니다. 이 문서에서는 주요 3D 프린팅 프로세스에 사용되는 다양한 유형의 파우더와 그 구성, 주요 특성, 응용 분야, 적용 사례에 대한 개요를 제공합니다.

탄탈륨 분말 공급업체 개요 탄탈륨 분말 공급업체는 전자, 화학, 금속 제조, 의료용 임플란트 및 항공우주 산업 전반에 걸쳐 사용되는 미세한 탄탈륨 금속 입자를 말합니다. 높은 융점, 밀도, 전기 전도도, 내식성과 같은 주요 특성으로 인해 고성능 제품에 대한 응용 분야가 확대되고 있습니다. 강력한 시장 수요와 복잡한

3D 프린팅 금속 분말 개요 3D 프린팅 금속 분말은 금속 부품 및 제품을 제작하기 위해 다양한 금속 적층 제조 공정에서 원료로 사용되는 미세한 금속 분말을 말합니다. 3D 프린팅에 사용되는 가장 일반적인 금속 분말에는 스테인리스 스틸, 티타늄, 니켈 합금, 알루미늄 등이 있습니다.

7050 알루미늄 합금 분말 개요 7050 알루미늄 합금 분말은 강하고 견고하며 열처리 가능한 합금 분말로 우수한 내피로성과 함께 고강도 특성을 가지고 있습니다. 아연이 주요 합금 원소인 7xxx 시리즈 알루미늄 합금의 일부입니다. 7050 합금 분말은 높은

티타늄 분말은 항공우주, 의료, 자동차 등 산업 전반의 다양한 용도에 이상적인 고유한 특성을 지닌 다용도 금속 분말입니다. 이 문서에서는 티타늄 분말에 대한 포괄적인 개요와 함께 유형, 구성, 특성, 용도, 사양, 가격, 장단점에 대한 세부 정보를 제공합니다,

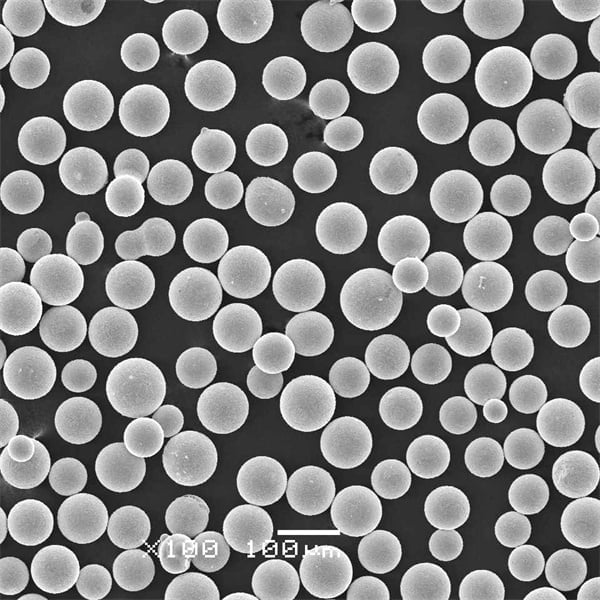

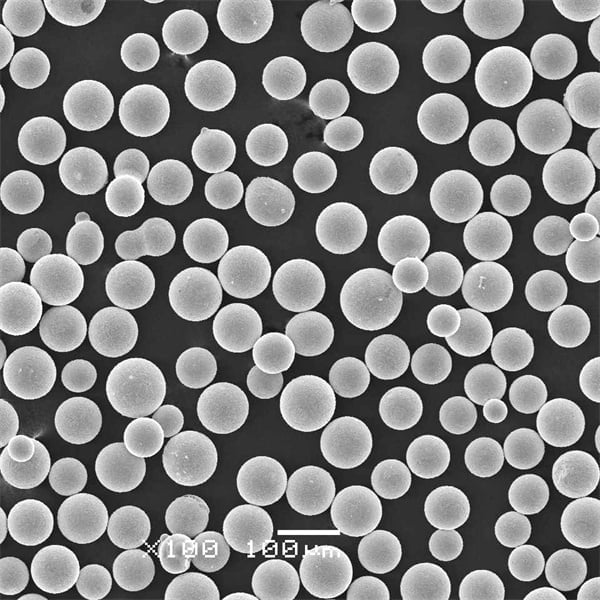

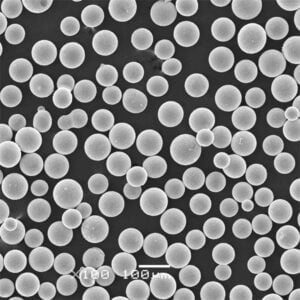

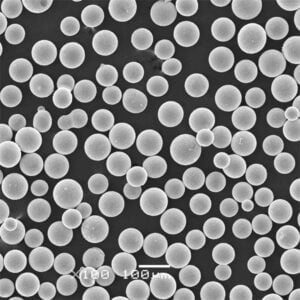

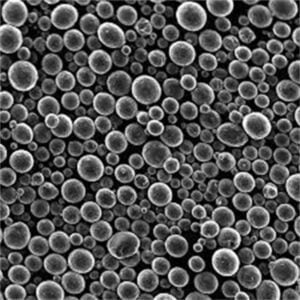

Spherical aluminum powder is a specialty aluminum powder with particles that are spherical in shape. This powder has several beneficial properties and applications compared to standard aluminum powders. Overview of spherical aluminum powder Spherical aluminum powder offers superior flowability, packing density, and other characteristics that make it well-suited to various

Overview of titanium gas atomizer equipment Titanium gas atomizer equipment refers to devices that are used to atomize (break down into fine particles) titanium metal for various applications. This equipment uses gas, typically argon, to atomize molten titanium into a spray of fine droplets. Some key details about titanium gas

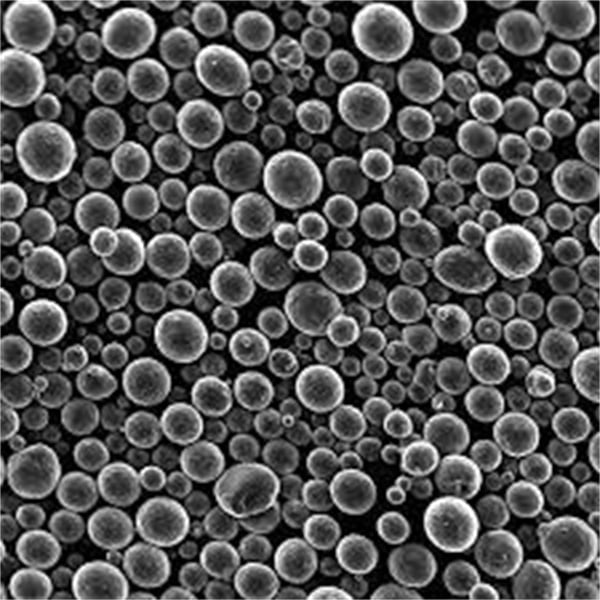

Overview of metal 3d printing powder Metal 3D printing powder refers to the raw material used in various metal additive manufacturing processes to produce three-dimensional metal parts layer by layer. Unlike traditional subtractive manufacturing that removes material, additive manufacturing builds up components by melting and fusing material together based on

3D printing technology relies on powdered material to build objects layer-by-layer. Selecting the right powder is critical for part quality, mechanical properties, accuracy, detail resolution, and surface finish. This article provides an overview of different types of powders used in major 3D printing processes, their composition, key properties, applications, and leading global suppliers. Overview of

Overview of Tantalum Powder Supplier tantalum powder supplier refers to fine particles of tantalum metal used across electronics, chemicals, metals manufacturing, medical implants, and aerospace industries. Key properties like high melting point, density, electrical conductivity, and corrosion resistance expand its applications for high-performance products. With strong market demand and complex supply chains, choosing a reputable

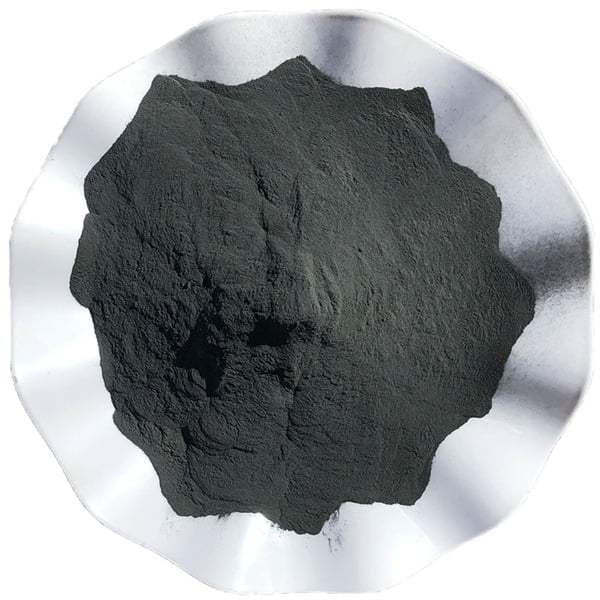

Overview of molybdenum powder Molybdenum powder refers to fine molybdenum particles in powder form used in various metallurgical, electronic, chemical, and industrial applications. Molybdenum has unique properties like high melting point, strength at high temperatures, corrosion resistance, thermal conductivity etc. that make it suitable for specialized uses. Key details about molybdenum powder: Molybdenum powder possesses

Overview of 3d printing metal powder 3D printing metal powder refers to fine metallic powders that are used as raw materials in various metal additive manufacturing processes to fabricate metal parts and products. The most common metal powders used for 3D printing include stainless steel, titanium, nickel alloys, aluminum, and cobalt-chrome. Metal powder bed fusion

Hastelloy is a registered trademark referring to a series of nickel-based superalloys that are known for their strength, durability, and corrosion resistance. Hastelloy powders are powders made from various Hastelloy alloys that are used in powder metallurgy and additive manufacturing processes. Overview of Hastelloy Powders Hastelloy powders provide exceptional high-temperature strength, outstanding resistance to oxidation

Overview of 7050 aluminium alloy powder 7050 aluminium alloy powder is a strong, tough, heat-treatable alloy powder that has high strength properties combined with excellent fatigue resistance. It is part of the 7xxx series of aluminium alloys, with zinc being the primary alloying element. 7050 alloy powder offers a high strength-to-weight ratio and is commonly

titanium powder is a versatile metal powder with unique properties that make it ideal for a wide range of applications across industries like aerospace, medical, automotive, and more. This article provides a comprehensive overview of titanium powder along with details on types, composition, properties, applications, specifications, pricing, pros and cons, and leading global suppliers. Overview

Spherical aluminum powder is a specialty aluminum powder with particles that are spherical in shape. This powder has several beneficial properties and applications compared to standard aluminum powders. Overview of spherical aluminum powder Spherical aluminum powder offers superior flowability, packing density, and other characteristics that make it well-suited to various industrial uses. Some key details:

Overview of titanium gas atomizer equipment Titanium gas atomizer equipment refers to devices that are used to atomize (break down into fine particles) titanium metal for various applications. This equipment uses gas, typically argon, to atomize molten titanium into a spray of fine droplets. Some key details about titanium gas atomizer equipment: Types of Titanium

Overview of metal 3d printing powder Metal 3D printing powder refers to the raw material used in various metal additive manufacturing processes to produce three-dimensional metal parts layer by layer. Unlike traditional subtractive manufacturing that removes material, additive manufacturing builds up components by melting and fusing material together based on a digital 3D model. Metal

3D 프린팅 및 적층 제조용 금속 분말