블로그

모든 컬렉션

스테인리스 스틸 파우더

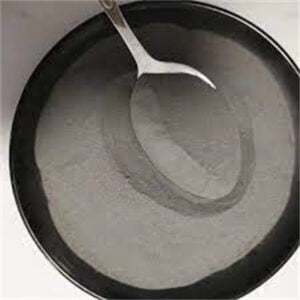

스테인리스 스틸 파우더는 다양한 산업 분야에서 활용되는 다용도 소재입니다. 이 종합 가이드는 스테인리스 분말의 다양한 측면에 대한 자세한 정보를 제공하여 이 소재에 대한 이해를 돕습니다. 스테인리스강 분말 개요 스테인리스강 분말은 스테인리스강을 분쇄한 후

7075 알루미늄 합금 분말

7075 알루미늄 합금 분말 개요 7075 알루미늄 합금 분말은 기계적 특성과 내식성이 우수한 강하고 가벼운 분말 야금 소재입니다. 마그네슘, 구리와 함께 아연을 주요 합금 원소로 함유하고 있어 많은 강철에 필적하는 매우 높은 강도를 제공합니다. 7075 알루미늄 합금

3D 프린팅 티타늄 분말

3D 프린팅 티타늄 분말 개요 티타늄은 강하고 가벼우며 부식에 강한 금속으로 항공우주, 자동차, 의료 및 기타 까다로운 응용 분야의 복잡한 형상을 3D 프린팅하는 데 이상적입니다. 티타늄 분말은 다음과 같은 파우더 베드 융합 기술을 사용하여 우수한 기계적 특성을 가진 고밀도 금속 부품을 프린트하는 데 사용할 수 있습니다.

eBM 제조 프로세스

전자빔 용융(EBM)은 전자빔을 사용하여 금속 분말을 층별로 선택적으로 녹여 완전히 조밀한 부품을 만드는 적층 제조 공정입니다. EBM 제조 공정은 복잡한 고성능 금속 부품을 생산하기 위해 기존 제조 방법을 뛰어넘는 기능을 제공합니다. EBM 제조 공정 개요 EBM은 다음과 유사하게 작동합니다.

금속 분무 제조업체

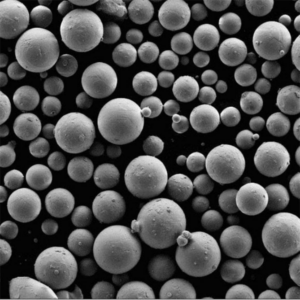

금속 분무 개요 금속 분무는 용융 금속을 고속으로 강제 분사하는 가스 또는 액체를 사용하여 미세한 방울로 분해하는 공정입니다. 이 방울은 적층 제조 또는 금속 사출 성형에 이상적인 구형 또는 원형 형태의 분말로 빠르게 응고됩니다. 원자화는 일관된

3D 프린팅 알루미늄 합금

3d printing aluminum alloys offer several beneficial characteristics like high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance that make them suitable materials for 3D printing applications across automotive, aerospace, consumer goods, and other industries. Selective laser melting (SLM) and direct metal laser sintering (DMLS) are the primary 3D printing

3D 프린팅 파우더 공급업체

3D 프린팅 파우더 공급업체 개요 적층 제조라고도 하는 3D 프린팅 파우더는 파우더를 원료로 사용하여 구성 요소를 층층이 쌓아 올립니다. 분말은 열, 레이저 또는 바인딩 에이전트를 사용하여 서로 융합되거나 결합되어 3차원 물체를 만듭니다. 다음과 같은 몇 가지 기술이 사용됩니다.

몰리브덴 분말

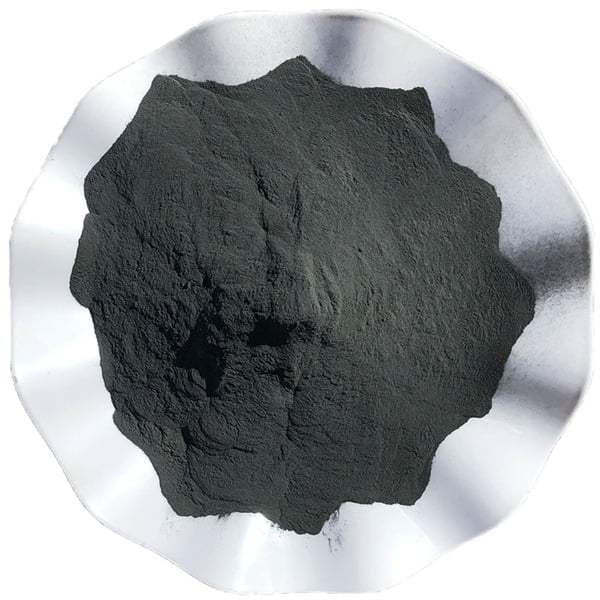

Molybdenum powder is a gray powder made by reducing molybdenum oxide under hydrogen atmosphere. It has unique properties like high melting point, strength, hardness, wear resistance, and ability to withstand extreme temperatures that make it suitable for applications like metallurgy, machinery manufacturing, electronics, and aerospace components. Overview of Molybdenum Powder Molybdenum powder has following key

고순도 금속 분말

High purity metal powders refer to metallic powders with extremely low levels of impurities, often 99.9% pure or higher. They are utilized across a wide range of advanced applications where contamination-free materials are critical for performance and reliability. Overview of High Purity Metal Powders High purity metal powders possess unique properties that make them indispensable

스테인리스 스틸 파우더

Stainless steel powder is a versatile material with applications across many industries. This comprehensive guide provides detailed information on various aspects of stainless steel powder to help you understand this material. Overview of Stainless Steel Powder Stainless steel powder is made from stainless steel that has been crushed into a fine powder form. It exhibits

금속 분말 소개

Metal powders are fine metal particles used in various manufacturing processes to create metal parts and products. This article provides an in-depth guide on metal powders covering their key properties, production methods, applications, suppliers, costs, and more. Overview of Metal Powders Metal powders are composed of fine particles of metal materials that can be used

7075 알루미늄 합금 분말

Overview of 7075 aluminium alloy powder 7075 aluminium alloy powder is a strong, lightweight powder metallurgy material with excellent mechanical properties and corrosion resistance. It contains zinc as the primary alloying element along with magnesium and copper which give it very high strength comparable to many steels. 7075 aluminium alloy powder can be used to

3D 프린팅 티타늄 분말

Overview of 3d printing titanium powder Titanium is a strong, lightweight, corrosion-resistant metal that is ideal for 3D printing complex geometries for aerospace, automotive, medical, and other demanding applications. Titanium powder can be used to print full-density metal parts with excellent mechanical properties using powder bed fusion technologies like selective laser melting (SLM) and electron

eBM 제조 프로세스

Electron Beam Melting (EBM) is an additive manufacturing process that uses an electron beam to selectively melt metal powder layer-by-layer to build up fully dense parts. ebm manufacturing process offers capabilities beyond conventional manufacturing methods for producing complex, high-performance metal parts. Overview of ebm manufacturing process EBM works similarly to other powder bed fusion techniques.

금속 분무 제조업체

Overview of Metal Atomization Metal atomization is a process where molten metal is broken into fine droplets using gas or liquid that is forced at high velocity. The droplets rapidly solidify into powder with a spherical or round morphology ideal for additive manufacturing or metal injection molding. Atomization produces consistent powder sizes ranging from 10

3D 프린팅 알루미늄 합금

3d printing aluminum alloys offer several beneficial characteristics like high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance that make them suitable materials for 3D printing applications across automotive, aerospace, consumer goods, and other industries. Selective laser melting (SLM) and direct metal laser sintering (DMLS) are the primary 3D printing processes used for aluminum alloy

3D 프린팅 파우더 공급업체

Overview of 3d printing powders suppliers 3d printing powders, also known as additive manufacturing, uses powders as the raw material to construct components layer by layer. The powders are fused or bound together using heat, laser, or binding agents to create three dimensional objects. There are several technologies used in 3D printing like Selective Laser

제품

인기 판매 제품

3D 프린팅 및 적층 제조용 금속 분말

연락처 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731