블로그

모든 컬렉션

DMLS 기술의 과제

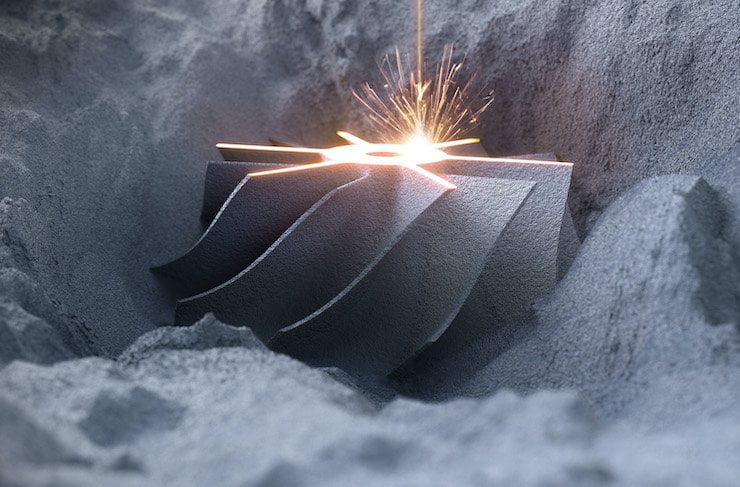

선택적 레이저 용융(SLM)이라고도 하는 직접 금속 레이저 소결(DMLS)은 금속 가공에 혁명을 일으켰습니다. 레이저 빔을 사용하여 금속 분말이 담긴 통에서 복잡한 고강도 부품을 만들어낸다고 상상해 보세요. 이것이 바로 DMLS의 마법입니다. 하지만 다른 강력한 기술과 마찬가지로 DMLS에도 어려움이 없는 것은 아닙니다. 안전벨트를 매고

DMLS 기술의 장점

DMLS(직접 금속 레이저 소결)는 금속 적층 제조 분야의 판도를 바꾸고 있습니다. 기존의 감산 제조 방식이 필요 없이 디지털 파일에서 직접 복잡한 고성능 금속 부품을 제작할 수 있는 기술을 상상해 보세요. 이것이 바로 DMLS의 마법입니다. 하지만 DMLS의 장점은 무엇일까요?

DMLS 기술의 프로세스 단계

허공에서 복잡한 금속 물체를 만들어내는 꿈을 꾸어본 적이 있나요? 직접 금속 레이저 소결(DMLS) 기술을 사용하면 그 꿈이 현실이 됩니다. 선택적 레이저 용융(SLM)이라고도 하는 DMLS는 고출력 레이저를 사용하여 금속 분말 입자를 정교하게 융합하는 혁신적인 3D 프린팅 프로세스입니다.

금형 분야에서의 DMLS 기술 적용

금형 설계가 한계를 뛰어넘는 세상을 상상해 보세요. 복잡한 형상과 내부 냉각 채널이 더 이상 장애물이 아니라 기회가 되는 세상. 이것이 바로 금형 제작 환경을 혁신하는 직접 금속 레이저 소결(DMLS) 기술이 가져온 현실입니다. 지금부터 DMLS 금형의 세계에 대해 자세히 알아보겠습니다,

의료 분야에서의 DMLS 기술 적용

외과의사가 환자의 고유한 해부학적 구조에 완벽하게 맞는 맞춤형 기구를 사용하여 수술할 수 있는 세상을 상상해 보세요. 자연 구조를 모방한 정교한 임플란트로 손상된 뼈를 복구하여 더 빠른 치유와 기능 향상을 도모할 수 있는 미래를 상상해 보세요. 이것이 바로 DMLS 기술이 가져올 현실입니다.

자동차 분야에서의 DMLS 기술 적용

자동차 제조업체가 복잡한 엔진 부품, 경량 섀시 부품, 심지어 맞춤형 인테리어까지 비교할 수 없는 정밀도와 자유로운 디자인으로 제작할 수 있는 세상을 상상해 보세요. 이것은 공상 과학 소설이 아니라 자동차 산업을 빠르게 변화시키고 있는 직접 금속 레이저 소결(DMLS) 기술의 현실입니다. 안전벨트를 매세요, 자동차 전문가 여러분.

항공우주 분야에서의 DMLS 적용

Imagine crafting intricate aircraft parts with unparalleled design freedom, slashing weight while boosting performance – that’s the magic of Direct Metal Laser Sintering (DMLS) in the aerospace industry. This revolutionary 3D printing technology is rapidly transforming how we design, manufacture, and utilize components in airplanes, satellites, and beyond. Buckle up,

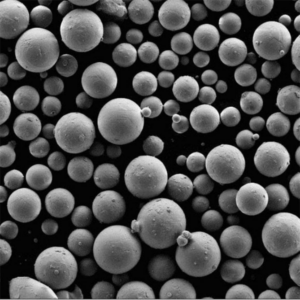

DMLS에 적합한 3D 프린팅 금속 분말

Imagine crafting complex metal objects with unparalleled precision, all from the comfort of your workshop. That’s the transformative power of Direct Metal Laser Sintering (DMLS), a 3D printing technology revolutionizing the manufacturing landscape. But this metallic metamorphosis hinges on a crucial ingredient: the metal powder itself. Not just any powder

직접 금속 레이저 소결(DMLS) 소개

the Magic of 3D Printing Metal Imagine a world where complex metal parts materialize from a bed of powder, layer by layer, with laser precision. This isn’t science fiction; it’s the reality of Direct Metal Laser Sintering (DMLS), a revolutionary 3D printing technology that’s transforming how we design and manufacture

바인더 제팅 소개

Imagine a 3D printer that builds objects layer by layer, not with melted plastic or lasers, but with a sprinkling of powder and a strategic squirt of glue. That’s the magic of binder jetting, an additive manufacturing (AM) technique rapidly gaining traction for its speed, affordability, and diverse material compatibility. This guide dives deep into

DMLS 기술의 과제

Direct Metal Laser Sintering (DMLS), also known as Selective Laser Melting (SLM), has revolutionized metalworking. Imagine conjuring complex, high-strength components from a vat of metal powder using a laser beam – that’s the magic of DMLS. But like any powerful technology, DMLS isn’t without its challenges. Buckle up as we delve into the intricate world

DMLS 기술의 장점

DMLS, or Direct Metal Laser Sintering, has become a game-changer in the world of metal additive manufacturing. Imagine a technology that can craft intricate, high-performance metal parts directly from a digital file, eliminating the need for traditional subtractive manufacturing methods. That’s the magic of DMLS. But what exactly makes DMLS so advantageous? Let’s delve into

DMLS 기술의 프로세스 단계

Have you ever dreamt of conjuring complex metal objects from thin air? Well, with Direct Metal Laser Sintering (DMLS) technology, that dream becomes a reality. DMLS, also known as Selective Laser Melting (SLM), is a revolutionary 3D printing process that uses a high-powered laser to meticulously fuse metal powder particles together, layer by layer, to

금형 분야에서의 DMLS 기술 적용

Imagine a world where mold design transcends limitations. Where intricate geometries and internal cooling channels are no longer obstacles, but opportunities. This is the reality ushered in by Direct Metal Laser Sintering (DMLS) technology, revolutionizing the mold-making landscape. Buckle up, because we’re diving deep into the world of DMLS molds, exploring the how, the what,

의료 분야에서의 DMLS 기술 적용

Imagine a world where surgeons can operate with custom-made instruments perfectly suited for a patient’s unique anatomy. Picture a future where damaged bones can be repaired with intricate implants that mimic the natural structure, promoting faster healing and improved functionality. This is the reality DMLS technology is bringing to the medical field, and it’s nothing

자동차 분야에서의 DMLS 기술 적용

Imagine a world where car manufacturers can craft intricate engine components, lightweight chassis parts, and even customized interiors – all with unparalleled precision and design freedom. This isn’t science fiction; it’s the reality of Direct Metal Laser Sintering (DMLS) technology rapidly transforming the automotive industry. Buckle up, gearheads, because we’re about to delve into the

항공우주 분야에서의 DMLS 적용

Imagine crafting intricate aircraft parts with unparalleled design freedom, slashing weight while boosting performance – that’s the magic of Direct Metal Laser Sintering (DMLS) in the aerospace industry. This revolutionary 3D printing technology is rapidly transforming how we design, manufacture, and utilize components in airplanes, satellites, and beyond. Buckle up, as we delve into the

DMLS에 적합한 3D 프린팅 금속 분말

Imagine crafting complex metal objects with unparalleled precision, all from the comfort of your workshop. That’s the transformative power of Direct Metal Laser Sintering (DMLS), a 3D printing technology revolutionizing the manufacturing landscape. But this metallic metamorphosis hinges on a crucial ingredient: the metal powder itself. Not just any powder will do; DMLS demands meticulously

직접 금속 레이저 소결(DMLS) 소개

the Magic of 3D Printing Metal Imagine a world where complex metal parts materialize from a bed of powder, layer by layer, with laser precision. This isn’t science fiction; it’s the reality of Direct Metal Laser Sintering (DMLS), a revolutionary 3D printing technology that’s transforming how we design and manufacture metal components. DMLS, also known

제품

인기 판매 제품

3D 프린팅 및 적층 제조용 금속 분말

연락처 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731