블로그

모든 컬렉션

강철 방울의 빠른 응고

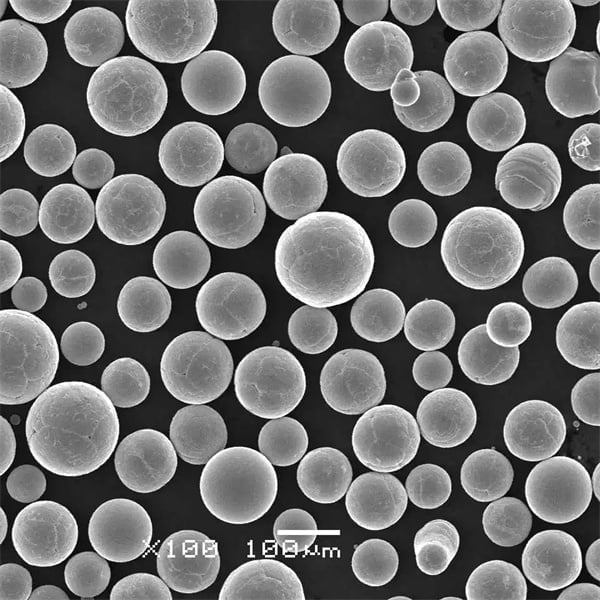

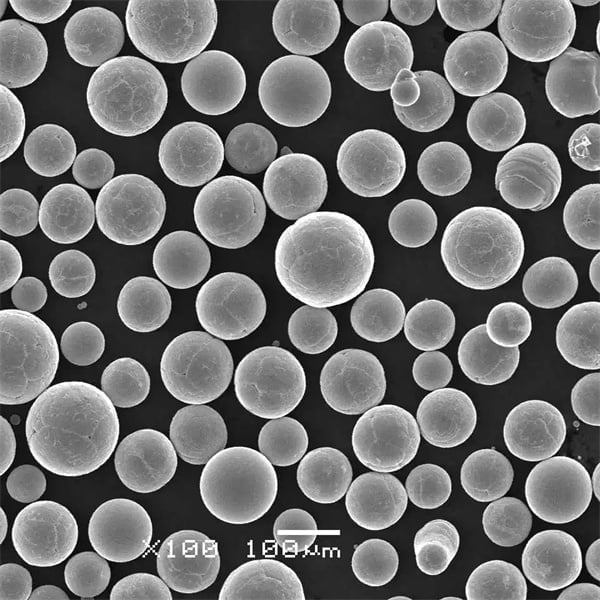

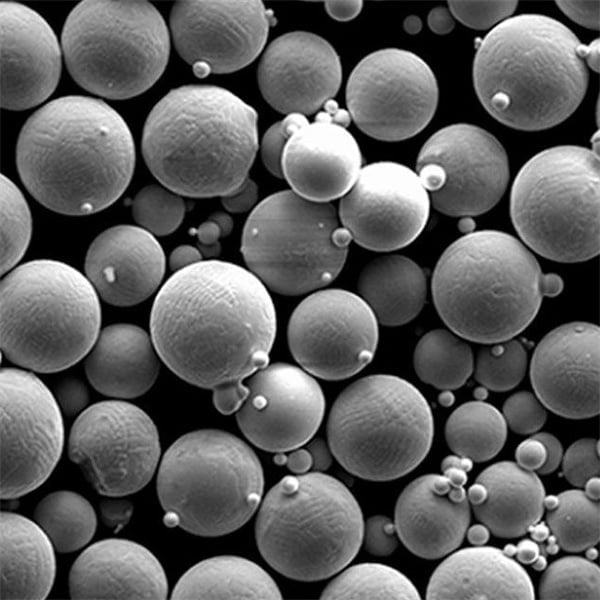

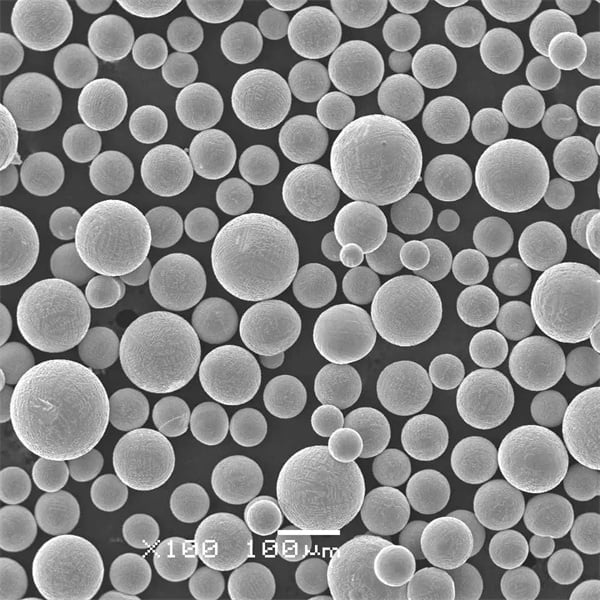

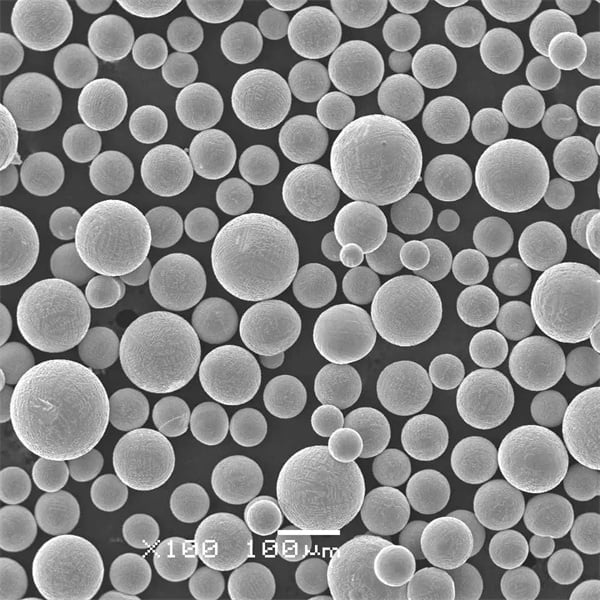

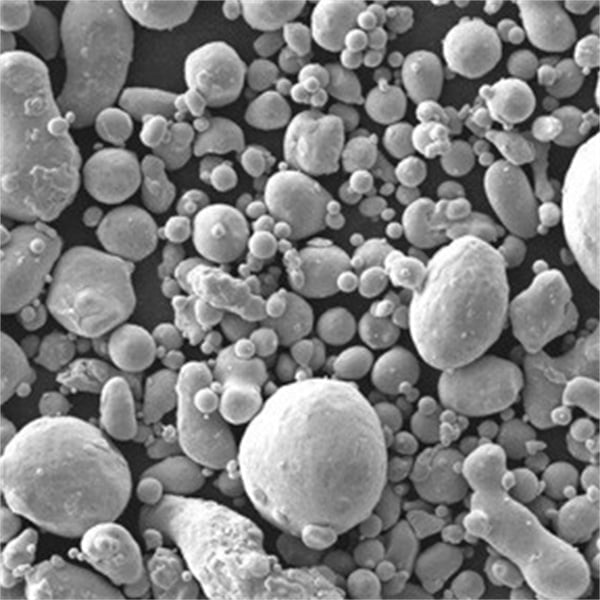

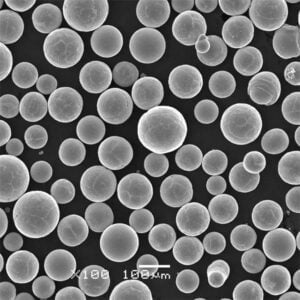

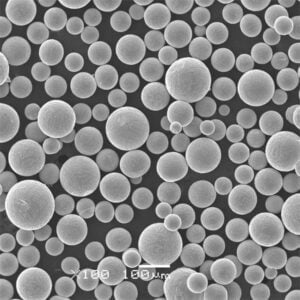

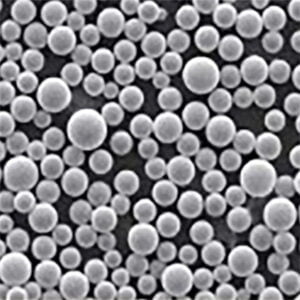

개요 급속 응고는 야금 분야, 특히 강철 액적 생산 분야의 최첨단 기술입니다. 이 공정에는 용강을 초고속으로 냉각시켜 재료의 특성을 향상시키는 미세한 미세 구조를 형성하는 과정이 포함됩니다. 이 글에서 우리는 급속 응고의 세부 사항에 대해 자세히 알아볼 것입니다.

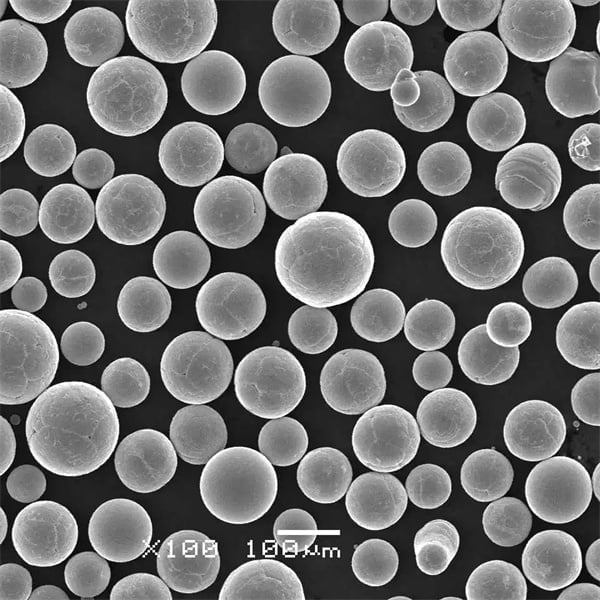

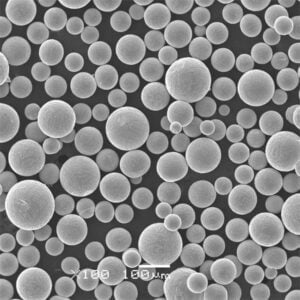

고순도 분말 생산 공정

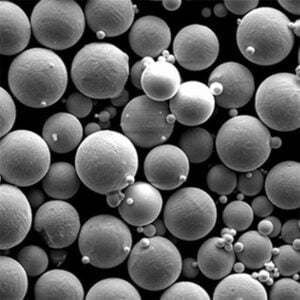

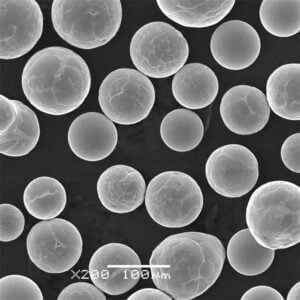

재료가 비교할 수 없을 정도로 정밀하게 제작되고 구조가 너무 순수하여 획기적인 응용이 가능한 세상을 상상해 보십시오. 이는 다양한 산업 전반에 걸쳐 성능의 한계를 뛰어 넘는 고순도 분말, 미세한 경이로움의 영역입니다. 그러면 이 작은 거인들은 어떻게 탄생하게 되었나요? 버클을 채우세요. 우리는 다이빙 중이니까요.

선택적 전자빔 용융

비교할 수 없는 정밀도와 가장 까다로운 재료도 처리할 수 있는 능력으로 복잡한 금속 물체를 층별로 제작한다고 상상해 보십시오. 이것이 금속 부품을 설계하고 제조하는 방식을 변화시키는 혁신적인 3D 프린팅 기술인 선택적 전자빔 용해(SEBM)의 마법입니다. 선택적 전자빔이란 무엇입니까?

마르텐사이트 스테인리스 스틸

마텐자이트계 스테인리스 스틸: 그 이름은 마치 슈퍼히어로 영화에 나오는 이름처럼 들릴 수도 있지만, 이 경이로운 소재는 현실 세계에서 강력한 영향력을 발휘합니다. 녹과 부식에 강할 뿐만 아니라 놀라운 강도로 경화될 수 있는 금속을 상상해 보십시오.

회전식 분무

Rotary atomization, a technological marvel lurking beneath the seemingly mundane act of spraying, is a cornerstone of various industries. Imagine transforming a stream of liquid into a fine mist of tiny droplets – that’s the magic of rotary atomization. But this technology goes beyond mere aesthetics; it unlocks a world of possibilities, from creating high-performance

내화 합금 소개

Refractory alloys are fascinating materials that play a critical role in numerous high-temperature applications. They are designed to withstand extreme environments, such as those found in aerospace, nuclear reactors, and advanced manufacturing processes. This comprehensive guide will delve into the world of refractory alloys, discussing their types, properties, applications, and much more. Overview of Refractory

반응성 합금 소개

Types of Reactive Alloys Here, we present specific metal powder models of reactive alloys, detailing their compositions, properties, and characteristics. Alloy Model Composition Properties Characteristics Ti-6Al-4V Titanium, Aluminum, Vanadium High strength-to-weight ratio, corrosion-resistant Widely used in aerospace and biomedical implants NiTi (Nitinol) Nickel, Titanium Shape memory, superelasticity Used in medical devices and actuators Al-Mg (Magnalium)

강철 방울의 빠른 응고

Overview Rapid solidification is a cutting-edge technology in the field of metallurgy, particularly for the production of steel droplets. This process involves the ultra-quick cooling of molten steel to form fine microstructures that enhance the material’s properties. In this article, we’ll dive deep into the specifics of rapid solidification, the types of steel powders produced,

고순도 분말 생산 공정

Imagine a world where materials are crafted with unparalleled precision, their structure so pure it unlocks groundbreaking applications. This is the realm of high-purity powders, microscopic marvels that push the boundaries of performance across diverse industries. But how do these tiny titans come to be? Buckle up, because we’re diving deep into the fascinating processes

선택적 전자빔 용융

Imagine crafting complex metal objects layer by layer, with unparalleled precision and the ability to handle even the most challenging materials. That’s the magic of Selective Electron Beam Melting (SEBM), a revolutionary 3D printing technology that’s transforming the way we design and manufacture metal components. What is selective electron beam melting? selective electron beam melting

마르텐사이트 스테인리스 스틸

Martensitic stainless steel: the name might sound like something out of a superhero movie, but this wonder material packs a serious punch in the real world. Imagine a metal that’s not only resistant to rust and corrosion but can also be hardened to incredible strength – that’s the magic of martensitic stainless steel. In this

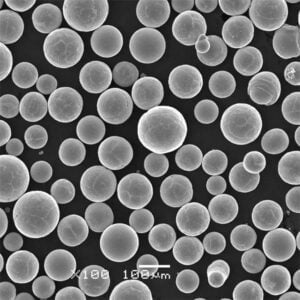

플라삼 원자화

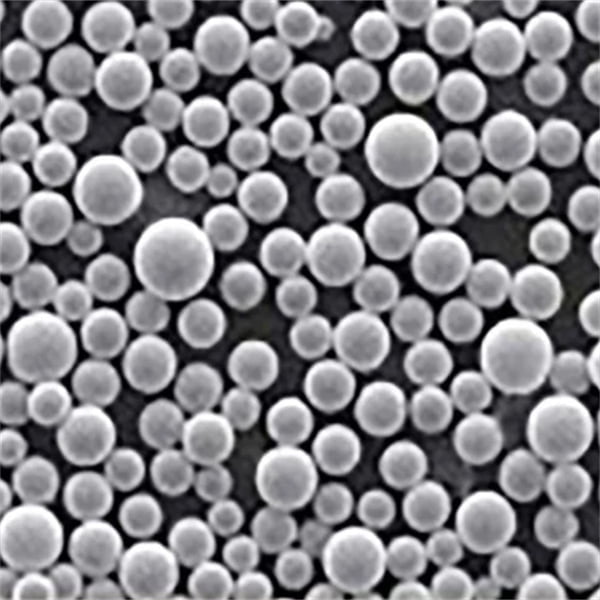

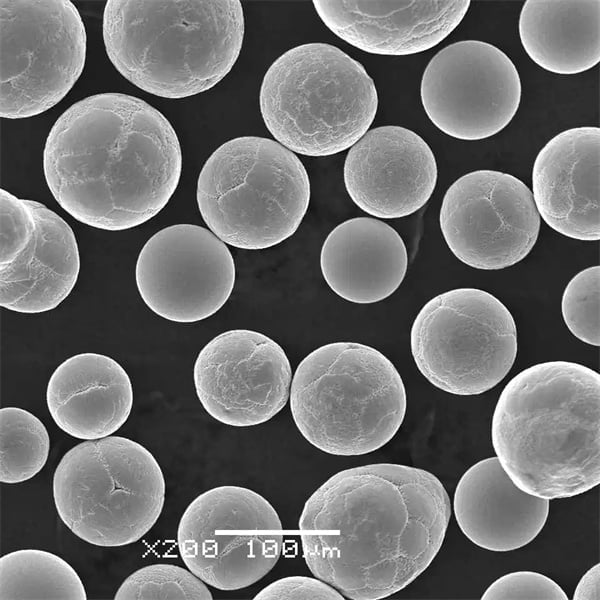

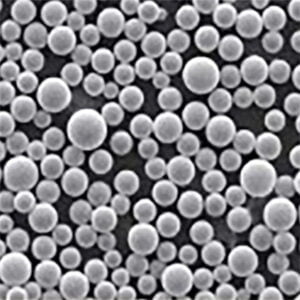

Imagine a sculptor, not wielding a chisel and hammer, but wielding a high-tech torch that breaks down molten metal into perfectly spherical particles. That’s the essence of plasam atomization, a transformative technology that’s revolutionizing the way we create advanced materials. What is plasam atomization? Plasma atomization utilizes the intense heat and power of plasma, a

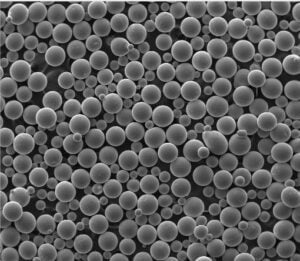

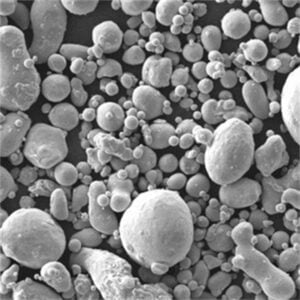

원자화 프로세스

Imagine a sculptor, meticulously chipping away at a massive block of stone, transforming it into a delicate figurine. The atomization process operates on a similar principle, but instead of chisels and stone, it utilizes high-powered jets to break down molten metals or liquids into minuscule, highly-functional particles. This article delves deep into the fascinating world

고주파 유도 용해

Imagine a furnace that heats metal not with flames or burning fuel, but with the invisible power of electricity. This isn’t science fiction; it’s the reality of high frequency induction melting, a revolutionary technology transforming the way we melt metals, particularly metal powders. What is High Frequency Induction Melting? High frequency induction melting (HFIM) utilizes

제품

인기 판매 제품

3D 프린팅 및 적층 제조용 금속 분말

연락처 정보

- 칭다오시, 산둥성, 중국

- [email protected]

- [email protected]

- +86 19116340731