개요

3D printing, also known as additive manufacturing (AM), utilizes metal powders to construct complex components layer by layer directly from digital models. The powders are selectively melted or bound by precision heat sources guided by the CAD model geometries.

Popular AM processes for metals include binder jetting, directed energy deposition, powder bed fusion, sheet lamination, and more. Each requires powder feedstock with specific characteristics to achieve optimal density, surface finish, dimensional accuracy, and mechanical properties.

This guide provides an in-depth look at metal powders for 3D printing, including alloy types, powder production methods, key powder properties, applications, specifications, suppliers, and purchasing considerations when sourcing material. Helpful comparison tables summarize technical data to assist with powder selection and qualification.

Connecting with knowledgeable suppliers of optimized 3D printing powders enables manufacturers to improve print quality, reduce defects, and fully leverage AM benefits like design freedom, faster iteration, and part consolidation.

Alloys for 3D Printing Powders

A wide range of metals and alloys are available in powder form suitable for AM processes:

Common Alloy Systems for 3D 프린팅 금속 분말

- 스테인리스 스틸

- 공구강

- 티타늄 및 티타늄 합금

- 알루미늄 합금

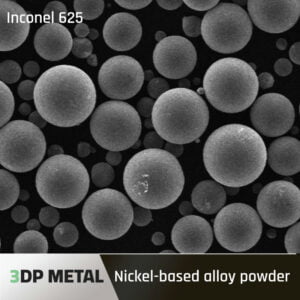

- 니켈 초합금

- 코발트-크롬 합금

- 구리 합금

- 귀금속

Both standard and custom alloys can be sourced to meet specific application requirements in terms of corrosion resistance, strength, hardness, conductivity, or other properties.

적층 제조용 금속 분말 생산 방법

Additive manufacturing utilizes metal powders produced through:

Typical Metal Powder Manufacturing Methods for 3D Printing

- 가스 분무

- 물 분무

- 플라즈마 분무

- 전기 분해

- Carbonyl iron process

- 기계적 합금

- Metal hydriding/dehydriding

- 혈장 구상화

- 과립화

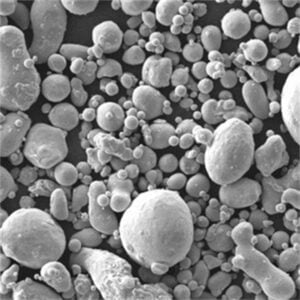

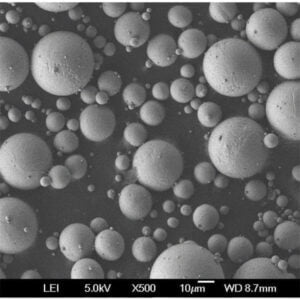

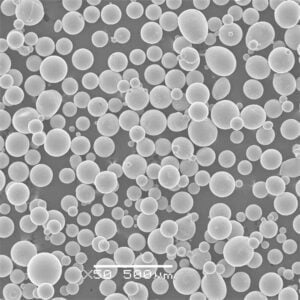

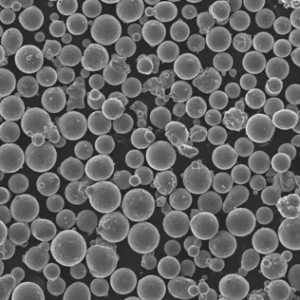

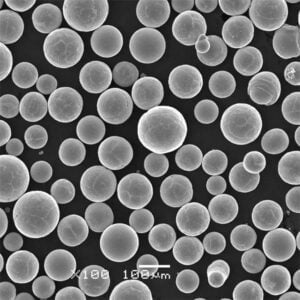

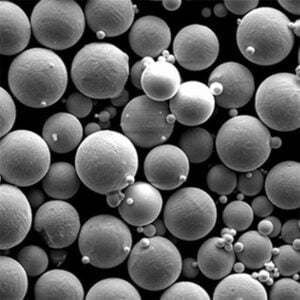

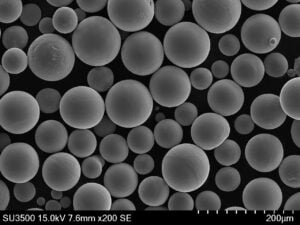

Spherical atomized powders provide optimal flow and dense packing needed for most AM processes. Some techniques allow nanoscale or customized alloy particles.

Key Characteristics of Metal Printing Powders

Critical powder characteristics for AM include:

Metal 3D Printing Powder Properties

| 특성 | 일반적인 값 | 중요성 |

|---|---|---|

| 입자 크기 분포 | 10~45미크론 | Affects densification, surface finish |

| 파티클 모양 | 구형 | Improves flow and packing |

| 겉보기 밀도 | 2 to 4 g/cc | Influences bed density |

| 탭 밀도 | 3 to 6 g/cc | Indicates compressibility |

| 홀 유량 | 25-50 s/50g | Ensures smooth powder spreading |

| 점화 시 손실 | 0.1-0.5% | Low moisture improves printing |

| 산소 함량 | <0.1% | Minimizes microstructural defects |

Precisely controlling characteristics like particle size, shape, and chemistry is critical to achieve fully dense AM parts with the desired mechanical properties.

응용 3D 프린팅 금속 분말

AM enables complex geometries impossible through conventional techniques:

Metal 3D Printing Applications

| 산업 | 용도 | 혜택 |

|---|---|---|

| 항공우주 | Turbine blades, structures | Design freedom, weight reduction |

| 의료 | 임플란트, 보철물, 기구 | Customized shapes |

| 자동차 | Lightweighting prototypes and tools | Rapid iteration |

| 방어 | Drone parts, protective structures | Quick prototypes and short runs |

| 에너지 | Heat exchangers, manifolds | Part consolidation and topology optimization |

| 전자 제품 | Shielding, cooling devices, EMI | Complex enclosed structures |

Lightweighting, part consolidation, and high-performance alloys for extreme environments provide key advantages over traditional manufacturing methods.

Specifications for 3D Printing Metal Powders

International specifications help standardize AM powder characteristics:

Metal Powder Standards for Additive Manufacturing

| 표준 | 범위 | 매개변수 | 테스트 방법 |

|---|---|---|---|

| ASTM F3049 | Guide for characterizing AM metals | Sampling, size analysis, chemistry, defects | Microscopy, diffraction, SEM-EDS |

| ASTM F3001-14 | Titanium alloys for AM | 입자 크기, 화학, 흐름 | 체질, SEM-EDS |

| ASTM F3301 | 적층 제조용 니켈 합금 | 입자 모양 및 크기 분석 | 현미경, 이미지 분석 |

| ASTM F3056 | AM용 스테인리스 스틸 | 화학, 분말 속성 | ICP-OES, 피크노메트리 |

| ISO/ASTM 52921 | 적층 제조 분말에 대한 표준 용어 | 정의 및 파우더 특성 | 다양한 |

공개된 사양을 준수하면 중요한 애플리케이션을 위한 반복 가능한 고품질 분말 공급 원료가 보장됩니다.

글로벌 공급업체 3D 프린팅 금속 분말

적층 제조에 최적화된 금속 분말을 공급하는 주요 글로벌 공급업체는 다음과 같습니다:

Metal Powder Manufacturers for 3D Printing

| 공급업체 | 재료 | 일반적인 입자 크기 |

|---|---|---|

| 샌드빅 | 스테인리스, 공구강, 니켈 합금 | 15-45 미크론 |

| 프렉스에어 | 티타늄, 초합금 | 10-45 미크론 |

| AP&C | 티타늄, 니켈, 코발트 합금 | 5-25 미크론 |

| 목수 첨가제 | 코발트 크롬, 스테인리스, 구리 | 15-45 미크론 |

| LPW 기술 | 알루미늄 합금, 티타늄 | 10-100 미크론 |

| EOS | 공구강, 코발트 크롬, 스테인리스강 | 20-50 미크론 |

많은 사람들이 바인더 분사, 파우더 베드 융합, 지향성 에너지 증착과 같은 일반적인 적층 제조 방법을 위해 특별히 설계된 미세 구형 분말에 집중하고 있습니다.

Purchasing Considerations for 3D Printing Metal Powder

Key aspects to discuss with metal powder suppliers:

- 원하는 합금 구성 및 특성

- 목표 입자 크기 분포 및 모양

- 봉투 밀도 및 홀 유동성

- 산소 및 수분과 같은 불순물 허용 수준

- 필수 테스트 데이터 및 분말 특성 분석

- 사용 가능한 수량 범위 및 리드 타임

- Special handling precautions for pyrophoric materials

- 품질 시스템 및 분말 원산지 추적성

- Technical expertise in AM-specific powder requirements

- 물류 및 배송 메커니즘

Work closely with suppliers experienced in optimized AM powders to ensure ideal powder selection for your process and components.

금속 3D 프린팅 파우더의 장단점

Benefits vs Limitations of Metal Powders for AM

| 장점 | 단점 |

|---|---|

| 복잡한 맞춤형 지오메트리 허용 | 기존 소재보다 높은 비용 |

| 개발 시간 대폭 단축 | 분말 취급 시 주의사항 |

| 어셈블리 및 경량화 간소화 | 인쇄된 부품에 후처리가 필요한 경우가 많습니다. |

| 단조 소재에 가까운 물성 구현 | 크기 및 빌드 볼륨 제약 조건 |

| Eliminates expensive dies, molds, tooling | 열 스트레스로 인해 균열 및 왜곡이 발생할 수 있습니다. |

| 부품 통합 및 토폴로지 최적화 지원 | 기존 방식보다 적은 생산량 |

| 구매 대 비행 비율 크게 향상 | 엄격한 분말 특성화 및 파라미터 개발이 필요합니다. |

When used appropriately, metal AM provides game-changing benefits but requires expertise to implement successfully.

자주 묻는 질문

How small can metal powder particle size be for AM?

Specialized atomization techniques can produce powder down to 1-10 microns, however most metals printers work best with minimum size around 15-20 microns for good flow and packing.

What causes poor surface finish in printed metal parts?

Surface roughness arises from partially melted powder adhered to surfaces, spatter, staircase stepping, and suboptimal melt pool characteristics. Using finer powders and dialing in ideal processing parameters smoothens finish.

Do all metal 3D printing methods work with the same powders?

While there is overlap, binder jetting generally uses a broader powder size distribution than powder bed fusion. Some processes are limited to certain alloys based on melting points or reactivity.

How are mixed or bimetallic powders made?

Prealloyed powders ensure uniform properties but for composites, physical powder blending or specialized atomization techniques provide blended elemental powder mixes.

How long does it take to change powder material in a metal printer?

A full purge and changeover between significantly different alloys requires 6-12 hours typically. Quick changes between similar materials can be under an hour.

결론

Optimized metal powders enable additive manufacturing processes to construct complex, robust metal components with superior properties. Matching alloy chemistry and powder characteristics to the printing method and component performance requirements is critical to high quality results. By partnering with experienced powder suppliers, end users leverage expertise in both powder production and 3D printing processes to develop robust AM components faster and more reliably.