Imagine a metal powder so versatile it can craft components for jet engines roaring at scorching temperatures, or delicate surgical instruments performing life-saving procedures. This isn’t science fiction; it’s the remarkable reality of cobalt chromium 3D printed metal powder.

This article delves deep into the world of cobalt chrome, exploring its properties, applications, production process, and the unique characteristics that make it a game-changer in additive manufacturing. So, buckle up and get ready to discover the metallic marvel revolutionizing industries.

The Advantages of Cobalt Chromium 3D Printing Metal Powder

Cobalt chromium (CoCr) isn’t your average metal dust. Here’s why it stands out in the 3D printing arena:

- 강도와 내구성: Imagine a material that can withstand the intense pressure and heat of a jet engine. CoCr boasts exceptional tensile strength, meaning it can bear significant pulling forces without breaking. It also exhibits remarkable resistance to wear and tear, making it ideal for long-lasting components.

- 내식성: Saltwater, harsh chemicals – CoCr shrugs them off! Its superior corrosion resistance makes it perfect for marine applications, medical implants, and components exposed to harsh environments. Think about it – hip replacements made from CoCr powder can endure the body’s fluids and movements for years.

- 생체 적합성: Not all metals are friendly to living tissues. The good news? CoCr is biocompatible, meaning it can coexist with the human body without causing adverse reactions. This characteristic makes it a top choice for orthopedic implants and other medical devices.

- 고온 성능: Imagine a metal that stays strong even when the heat is on. CoCr retains its mechanical properties at elevated temperatures, making it ideal for aerospace parts like turbine blades and engine components that face scorching conditions.

- 자유로운 디자인: 3D printing unlocks a world of design possibilities, and CoCr powder thrives in this environment. Its ability to be formed into complex shapes allows engineers to create intricate components with superior functionality.

결과는? Lighter, stronger, and more durable parts that push the boundaries of design and performance in various fields.

The Widespread Application of Cobalt Chromium 3D Printing Metal Powder

CoCr powder isn’t a one-trick pony. Its impressive properties translate into a diverse range of applications:

- 항공우주: From jet engine components to rocket parts, CoCr’s strength and heat resistance make it a natural fit for the demanding aerospace industry. Components like turbine blades and landing gear benefit from its ability to withstand extreme conditions.

- 의료: Think about the delicate tools a surgeon relies on during an operation. CoCr powder is used to create surgical instruments, implants like hip and knee replacements, and dental crowns due to its biocompatibility and durability.

- 자동차: The quest for lighter, stronger car parts is a constant battle. CoCr steps up by enabling the creation of high-performance components like gears and suspension parts that contribute to better fuel efficiency and handling.

- 석유 및 가스: The harsh environment of oil and gas exploration demands robust materials. CoCr powder finds its place here by being used in drilling tools and equipment that can handle extreme pressure and corrosive conditions.

- 소비재: From high-end bicycles to designer jewelry, CoCr powder is making its way into consumer products. Its potential for creating lightweight, intricate designs with a touch of luxury is attracting manufacturers across industries.

As 3D printing technology matures, we can expect even more innovative applications for CoCr powder to emerge.

생산 프로세스 Cobalt Chromium 3D Printed Metal Powder

So, how does this wonder powder come to life? The production process involves several meticulous steps:

- Raw Material Selection: The journey begins with high-purity cobalt and chromium powders. These are carefully chosen to meet specific quality and composition requirements.

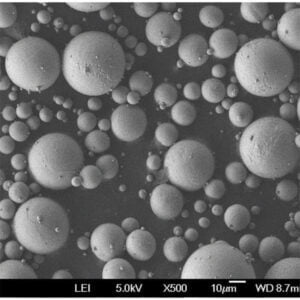

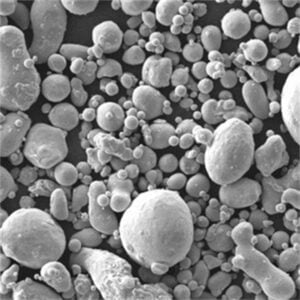

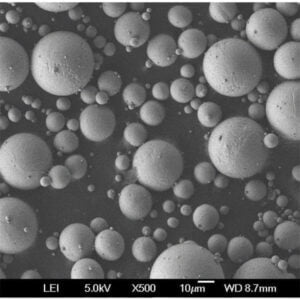

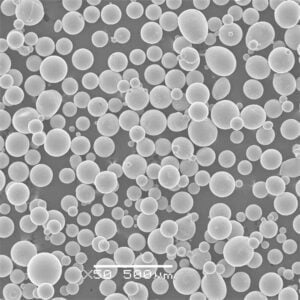

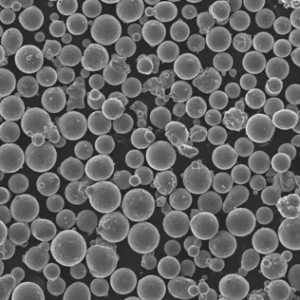

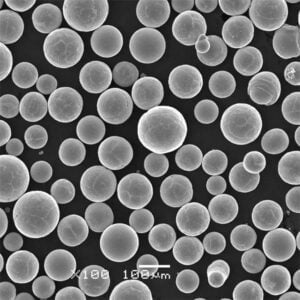

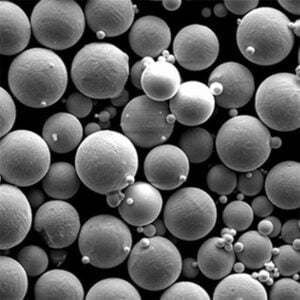

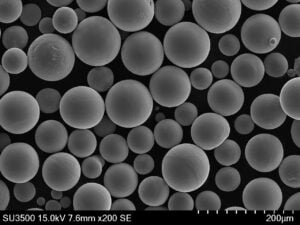

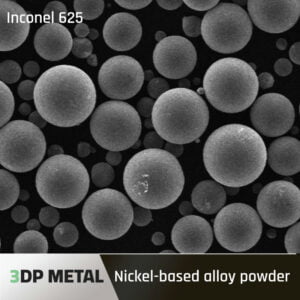

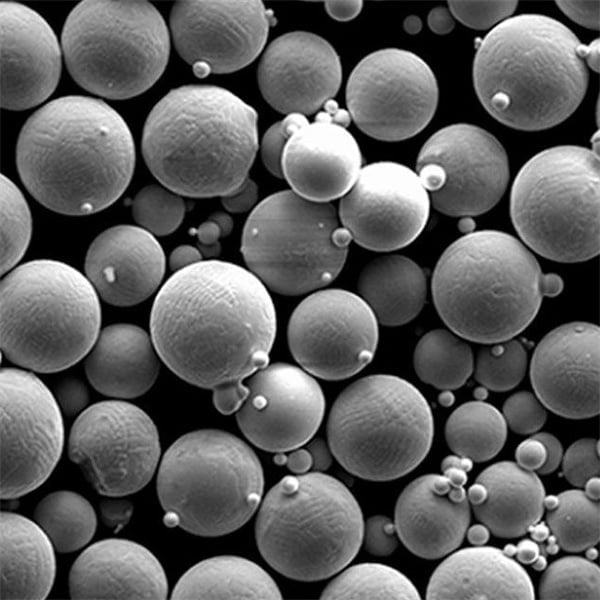

- 원자화: Here’s where things get interesting. The raw materials are melted at high temperatures and then rapidly atomized using techniques like gas or water atomization. This creates a fine mist of molten metal that solidifies into tiny spherical particles – our CoCr powder!

- 선별 및 분류: Not all powder particles are created equal. The resulting powder is sieved and classified to achieve a consistent particle size distribution. This ensures smooth flow during the 3D printing process and optimal part properties.

- Powder Characterization: Quality control is paramount. The CoCr powder undergoes rigorous testing to analyze its chemical composition, flowability, and particle size distribution. This ensures the powder meets the stringent requirements for 3D printing.

- 레이저 빔 용융(LBM): A high-powered laser beam selectively melts the CoCr powder layer by layer, building the desired 3D object. Imagine a laser wielding artist meticulously sculpting a metal masterpiece, one layer at a time. LBM offers exceptional accuracy and detail for intricate parts.

- 전자 빔 용융(EBM): Similar to LBM, but with a twist – EBM utilizes an electron beam in a vacuum environment for melting. This method is particularly well-suited for creating high-density, high-strength components for demanding applications.

Powder Characteristics of Cobalt Chromium 3D Printed Metal Powder

The magic of CoCr powder lies not just in its composition, but also in its physical characteristics:

- 입자 크기 및 분포: The size and distribution of the powder particles significantly impact the 3D printing process and final part properties. A consistent and optimal particle size distribution ensures smooth powder flow during printing, leading to better surface finish and mechanical strength in the finished part.

- 구형성: Imagine perfectly round marbles – that’s the ideal shape for CoCr powder particles. Highly spherical particles pack together efficiently, minimizing voids and promoting good flowability during printing. This translates to denser parts with superior mechanical properties.

- 흐름성: Just like pouring sand, CoCr powder needs to flow freely during the 3D printing process. Good flowability ensures even distribution of the powder across each layer, resulting in consistent part density and quality.

- 표면 모폴로지: The surface texture of the powder particles also plays a role. A smooth surface minimizes friction during printing, promoting better flowability and reducing the risk of defects.

By carefully controlling these characteristics, manufacturers can create CoCr powder that optimizes the 3D printing process and delivers high-performance parts.

Advantages and Considerations of Cobalt Chromium 3D Printing Metal Powder

While CoCr powder boasts numerous advantages, it’s essential to consider some factors:

장점:

- Broad range of applications: From aerospace to medicine, CoCr powder caters to diverse industries thanks to its versatility.

- 뛰어난 기계적 특성: Strength, wear resistance, and high-temperature performance make it ideal for demanding applications.

- 생체 적합성: A boon for the medical field, CoCr allows for the creation of implants that seamlessly integrate with the human body.

- 자유로운 디자인: Unlocks the potential for creating complex, lightweight structures with intricate details.

- 낭비 감소: Compared to traditional manufacturing methods, 3D printing with CoCr powder minimizes material waste.

고려 사항:

- 비용: CoCr powder itself and the 3D printing process can be expensive compared to some conventional techniques.

- 후처리: 3D printed CoCr parts may require additional post-processing steps like heat treatment or surface finishing to achieve desired properties.

- 안전: Handling CoCr powder requires proper safety precautions due to the presence of cobalt, which can be harmful if inhaled.

The decision to use CoCr powder depends on weighing its advantages against the considerations specific to each application.

자주 묻는 질문

Here’s a breakdown of some frequently asked questions about CoCr powder:

| 질문 | 답변 |

|---|---|

| What are the different types of CoCr powder available? | CoCr powder can come in various compositions, with varying ratios of cobalt and chromium. Additionally, some manufacturers offer alloyed versions with elements like molybdenum or tungsten for specific performance enhancements. |

| How long does it take to 3D print with CoCr powder? | Printing time depends on the size and complexity of the part. Simple objects can take a few hours, while intricate designs may require days. |

| What are the surface finish options for 3D printed CoCr parts? | The surface finish can be tailored through various post-processing techniques like machining, polishing, or sandblasting. |

| Is CoCr powder recyclable? | Yes, in many cases, CoCr powder can be recycled and reused in the 3D printing process, minimizing waste. |

| What are some of the future advancements expected in CoCr powder technology? | Researchers are continuously exploring ways to improve the affordability, printability, and performance of CoCr powder. We can expect advancements in powder characteristics, new alloying elements, and faster printing techniques. |

By understanding the properties, applications, and considerations of CoCr powder, you can make informed decisions about its suitability for your specific 3D printing projects.